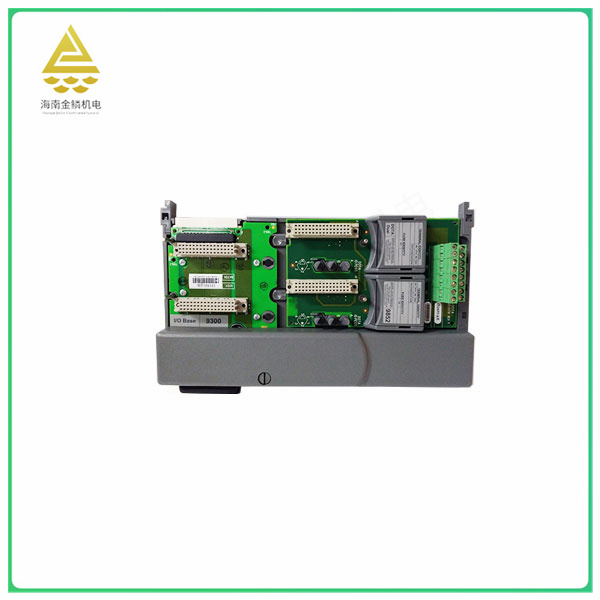

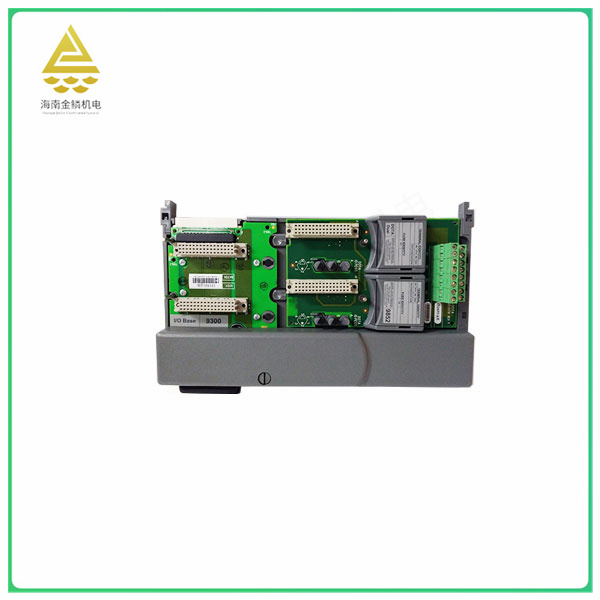

The 9300-9852-9852 is an industrial automation control module with a variety of functions and applications. Here are some of the main features and benefits of the module:

Multi-channel input/output capability: The 9300-9852-9852 module has multiple input/output channels, which can simultaneously collect and control multiple signals. This enables it to adapt to complex industrial automation control systems and realize monitoring and control functions of a variety of signals.

High reliability and stability: The module uses high-quality components and stable circuit design to work stably in harsh industrial environments. It has undergone strict quality control and testing to ensure the reliability and stability of long-term operation, reducing failure and maintenance costs.

Powerful processing power: The 9300-9852-9852 module is equipped with a high-performance processor capable of quickly processing various control algorithms and real-time data. It can ensure the real-time and accuracy of the system, and meet the needs of industrial automation control system for high-speed processing capacity.

A variety of communication interface and protocol support: the module supports a variety of communication protocols and interface standards, and can communicate with a variety of PLC, DCS, host computer and other devices. This makes it easy to exchange and control data with other devices to achieve system integration and interconnection.

Easy to configure and program: The 9300-9852-9852 module provides easy-to-use configuration software and programming interfaces that make it easy for engineers to configure and program. This reduces the difficulty of system development and integration, and improves work efficiency.

The 9300-9852-9852 module is suitable for a variety of industrial scenarios, especially in areas with high automation control and monitoring requirements. Here are some typical industrial scenarios for which the module is suitable:

Manufacturing: In manufacturing, the module can be used to automate production line control, equipment monitoring and process flow control. It can collect signals from various sensors and actuators, accurately control the production process, and improve production efficiency and product quality.

Power industry: In power systems, the module can be used to automate the monitoring and control of the power grid. It can communicate with various power equipment, monitor the operating status of the power grid in real time, and execute control commands to ensure the safe and stable operation of the power system.

Chemical industry: In the chemical production process, the module can be used to achieve automatic control of reaction processes, material handling and monitoring. It can accurately control the parameters of chemical reaction temperature, pressure, flow rate, etc., to improve production efficiency and safety.

Automated production lines: In automated production lines, this module can be used to implement the monitoring and control of equipment. It can collect the operating status and production data of the equipment, remote control and adjustment of the equipment, and improve production efficiency and quality.

Intelligent manufacturing: In the field of intelligent manufacturing, this module can be used to automate and intelligentize factories. It can be integrated with various sensors, actuators and control systems to achieve interconnection and data sharing between devices, improve production efficiency and reduce energy consumption.

It should be noted that the specific application scenarios may vary due to actual application requirements and technical conditions