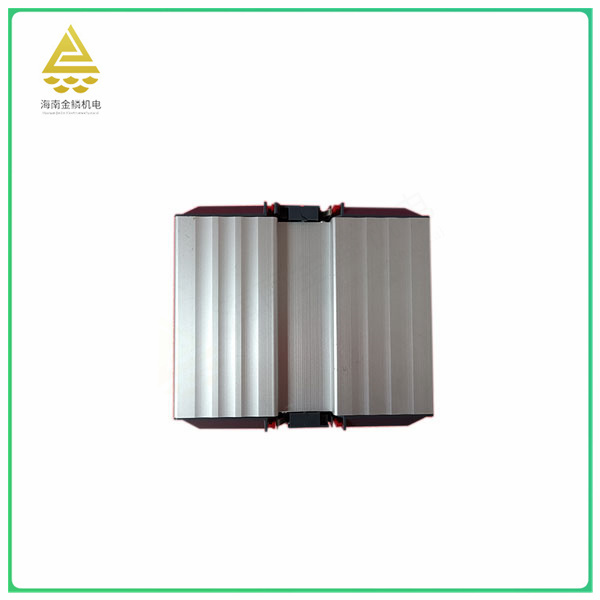

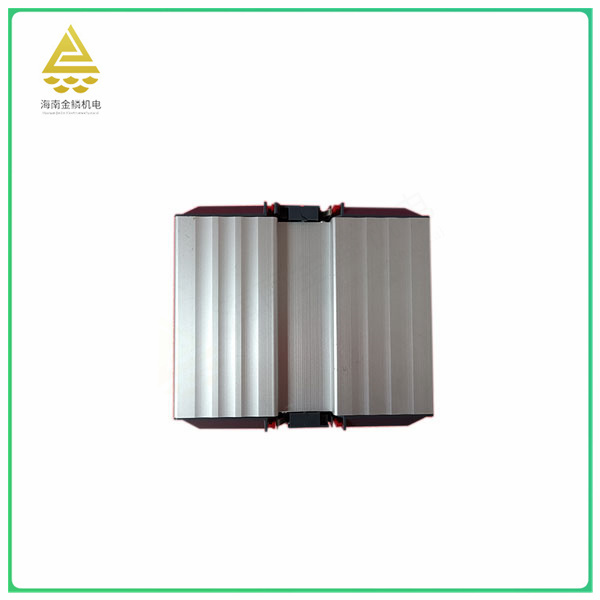

The D136-001-007 MooG hydraulic servo valve is an industrial control valve that measures the flow of hydraulic oil according to an input electrical signal or command, thereby controlling the position, speed, pressure or force in a type of machine or equipment (generally through a piston or plunger). It has a variety of characteristics:

Servo valves can be divided into single stage, double stage or three levels.

The hydraulic servo valve is composed of pilot stage, feedback mechanism and main stage.

The pilot stage receives input or command signals from the controller to provide the hydraulic pressure or mechanical force needed to move the main stage spool.

The feedback mechanism obtains the actual displacement from the main spool to the pilot stage through mechanical feedback (MFB) or electrical feedback (EFB).

The main stage spillage measures the flow as a function of the input signal, and the D136-001-007 provides mechanical or electrical feedback for the pilot stage.

In short, the D136-001-007 MooG hydraulic servo valve is a key component used in a wide range of industrial control systems to help achieve accurate, fast and stable control.

The function of D136-001-007 MooG hydraulic servo valve is mainly to control the flow of hydraulic oil according to the input electrical signal or command, so as to accurately control the position, speed, pressure or force of the machine or equipment. This control is usually achieved by means of a piston or plunger.

In the field of application, D136-001-007 Moog hydraulic servo valve is widely used in various industrial automation, aerospace, military, automotive engineering, simulation test and other fields. It is used to control a variety of mechanical, hydraulic, electric and pneumatic systems.

The advantages of servo valves include high precision, fast response, stability and reliability, which can realize complex motion control tasks and improve production efficiency and product quality. In the field of industrial automation, servo valves are widely used in the control system of various CNC machine tools, textile machinery, packaging machinery and other equipment to achieve high-precision and high-efficiency processing and production. In the aerospace field, servo valves are used to control the attitude and position of the aircraft to ensure its stability and safety. In the military field, servo valves are used to control the movement and strike of artillery, missiles and other weapon systems to improve combat efficiency and combat effectiveness. In the field of automotive engineering, servo valves are used to control vehicle suspension systems, braking systems, etc., to improve vehicle stability and safety. In the field of simulation testing, servo valves are used to simulate experimental environments under various physical conditions to provide accurate test data for scientific research and experiments.

In short, the D136-001-007 MooG hydraulic servo valve is an important control element, which has a wide range of applications in various industrial and scientific research fields, and can achieve accurate, fast and stable control and motion management tasks.