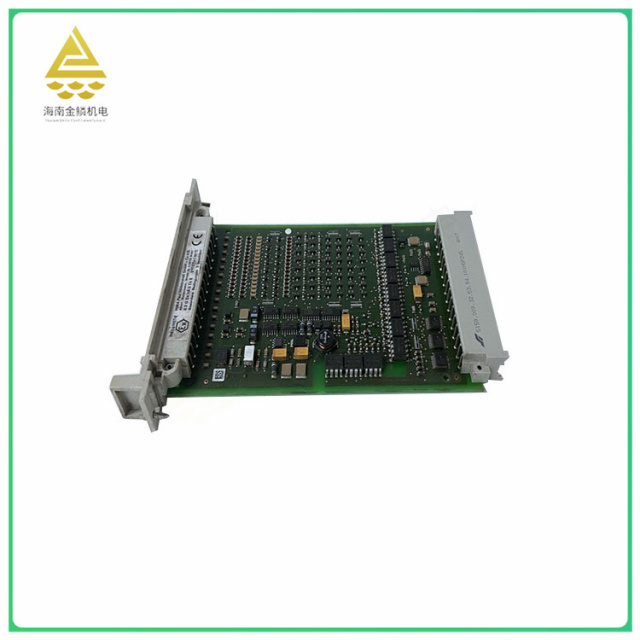

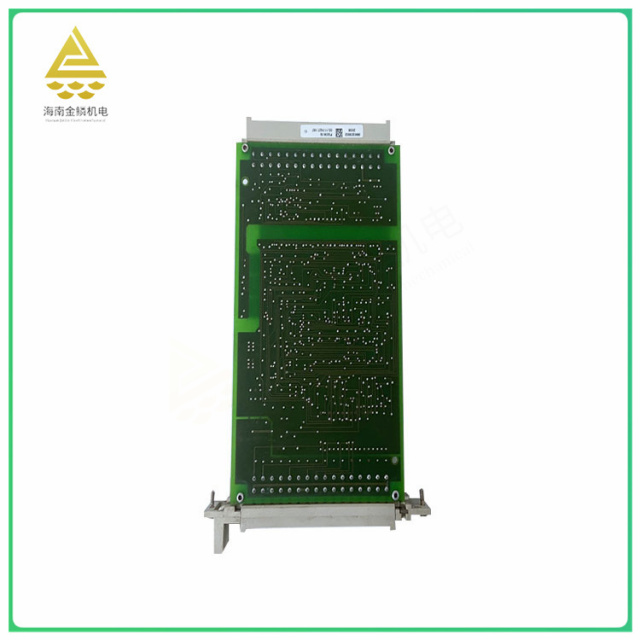

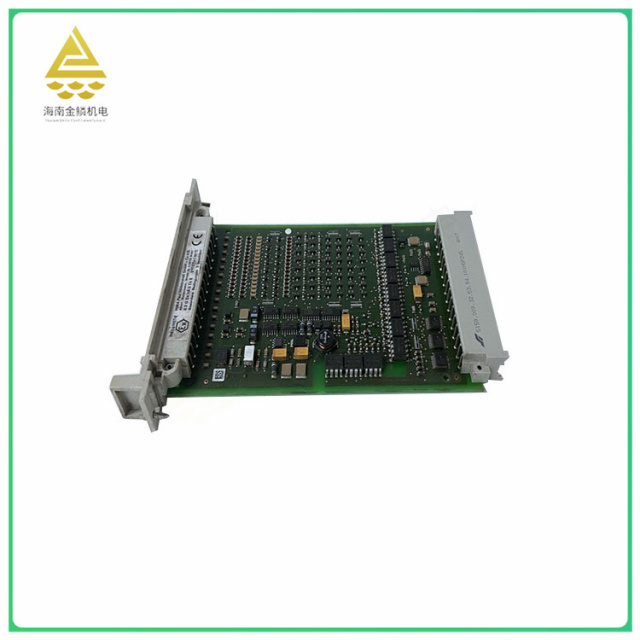

The HIMA f3236 module is a high-performance module designed for industrial automation applications. It provides advanced features and reliable performance to enhance process control and safety.

The F3236 is a digital input module commonly used in safety instrument control systems. It has a variety of input channels and can be configured to work in different modes to suit different application requirements. The F3236 has a typical switching time of 8 ms, a space requirement of 4 TE, and can be powered by 5 V DC or 24 V DC. In addition, the module is automatically fully tested during operation to ensure that its function is correct.

Benefits of the F3236 include:

High reliability: The module is manufactured with high-quality materials and processes, which can operate stably in harsh industrial environments to ensure the reliability and stability of the equipment.

Flexible configuration: The module has a variety of input channels, can be flexibly configured according to actual needs, to meet a variety of different industrial control needs.

Comprehensive test function: The module is automatically fully tested during operation to ensure that it functions correctly and reduces the risk of failure.

Easy maintenance: The modular design of the module makes maintenance simple and fast, and if a channel fails, the corresponding module can be easily replaced without the need to replace the entire system.

Disadvantages of the F3236 may include:

High cost: Because the module is manufactured with high-quality materials and processes, its cost is relatively high.

Professional maintenance required: The installation and maintenance of the module requires professional technicians to operate in order to ensure its normal operation and service life.

In summary, the F3236 is a highly reliable and flexible digital input module suitable for industrial control fields such as safety instrument control systems. However, it is expensive and requires professional maintenance and technical support. When choosing to use this module, enterprises should evaluate according to their actual needs and budget.

F3236 maintenance mainly includes the following aspects:

Cleaning: Periodically wipe the surface of the module with a dry rag to remove dust and dirt. Be careful to avoid using a cloth that is too wet to prevent moisture from seeping into the module.

Moisture-proof: Special care should be taken to keep the F3236 dry in humid environments. The module can be placed in a moisture-proof box or dryer to avoid short circuit or corrosion caused by moisture.

Shockproof: avoid severe vibration or impact, so as not to affect the electronic components inside the module. During transportation or installation, handle with care to avoid accidental drop or collision.

Periodic check: Periodically check whether the cables of the module are loose and whether the components of the module are abnormal. If any problem is found, it should be handled in time to avoid affecting the normal operation of the module.

Software updates: If the F3236 is equipped with relevant software, check the software regularly for updates. Install software updates in a timely manner to ensure that the functions and performance of the module are fully utilized.

Storage: In the case of long-term non-use, store the F3236 in a dry, cool place and keep its packaging intact. Avoid exposing the module to high temperature and humidity to avoid affecting its performance and service life.

To sum up, the maintenance of the F3236 mainly includes cleaning, moisture, shock resistance, regular inspection, software updates and proper storage measures.